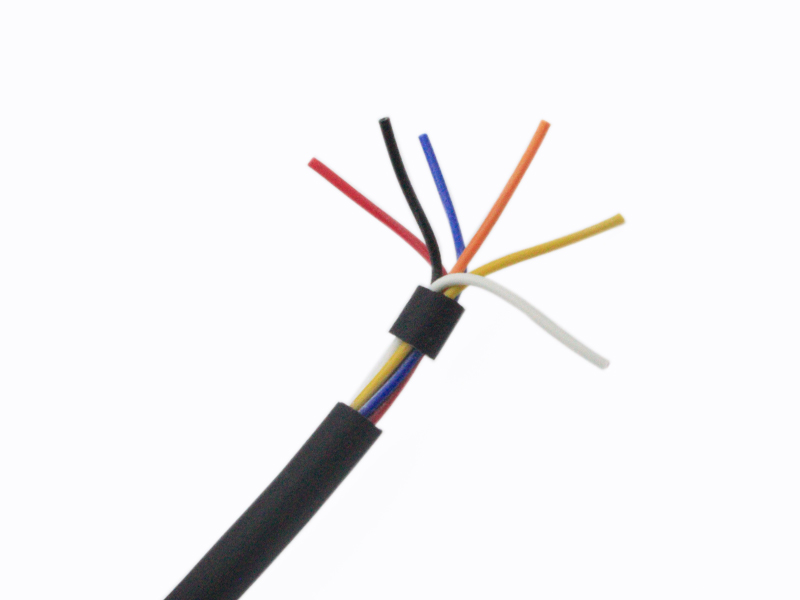

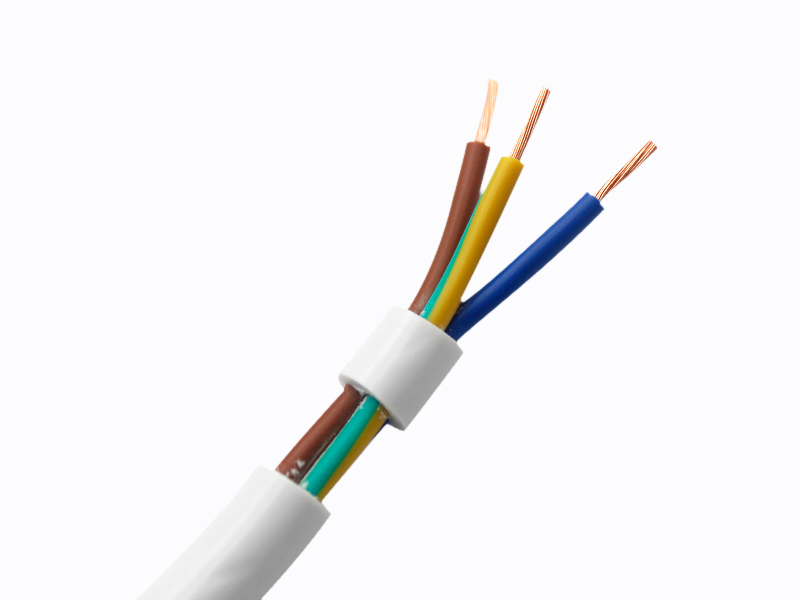

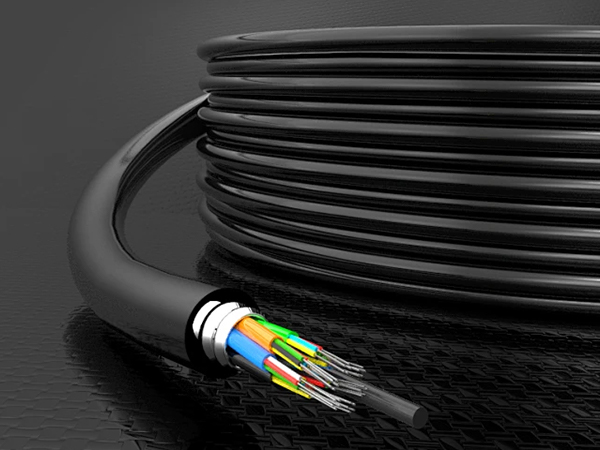

Products

About US

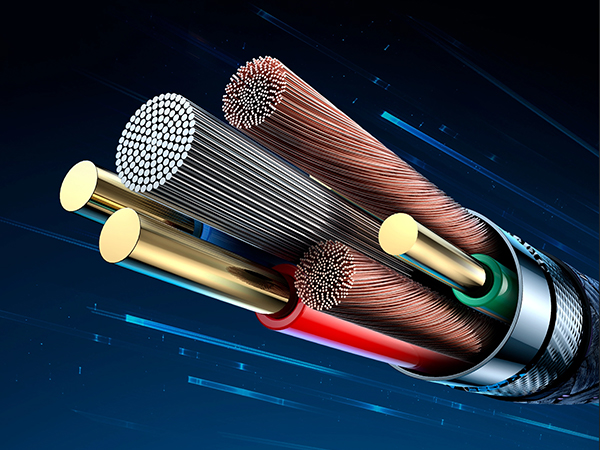

Dongguan Honglin Electronics (Honglin Technology) Co., Ltd. was founded in 2014, and its factory is located in Humen Town, Dongguan City, Guangdong Province. It is a wire and cable production enterprise with more than ten years of experience. The company integrates cable development, production, and sales, focusing on providing customers with high-quality cables and supporting services.

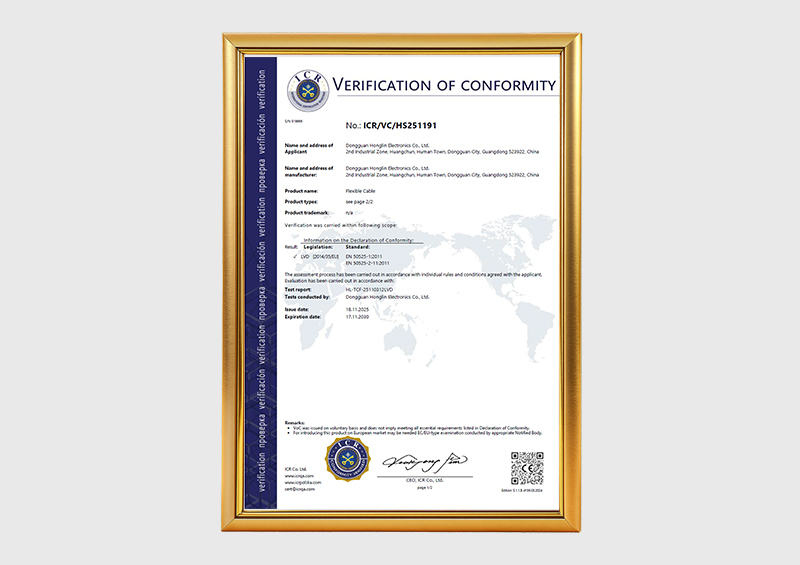

The company has passed ISO9001 international quality management system certification, and its products have obtained UL certification in the United States, CE certification in Europe, and other certifications. Strict material selection, strong technical strength, precise production and testing equipment, craftsmanship, and rigorous control provide strong guarantees for the cables produced by our company.

The company provides you with high-quality cables with over ten years of manufacturing experience, and quality is the foundation of the enterprise. Welcome domestic and international, new and old customers to visit and discuss cooperation!

-

+

Date of establishment

-

+

Number of employees

-

+

Patent certification

-

+

Factory area